The Duty of Plastic Injection Molding in Developing Cost-efficient Industrial Components

The Future of Plastic Injection Molding: Developments and fads to View

As the plastic shot molding sector evolves, a number of essential fads are arising that promise to improve its landscape. Automation and clever manufacturing strategies are set to boost productivity, while the change towards sustainable products reflects an expanding ecological consciousness.

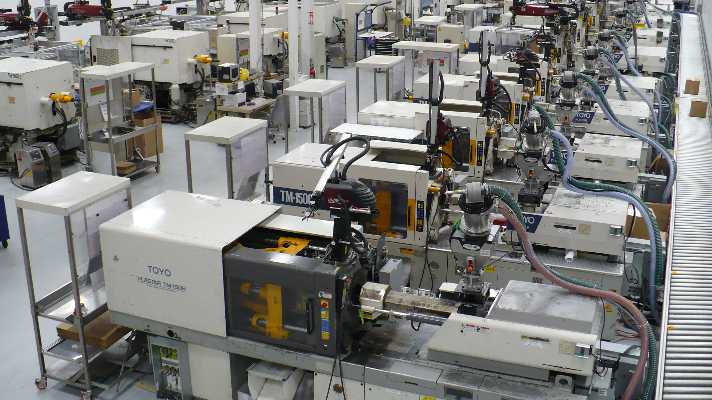

Automation and Smart Manufacturing

As the plastic shot molding sector evolves, automation and smart production are taking center stage, reinventing production processes - Plastic Injection Molding. The assimilation of advanced innovations such as robotics, IoT (Internet of Things), and expert system is enabling producers to boost efficiency, decrease operational prices, and improve product top quality. Automated systems streamline workflows, lessening manual intervention and enhancing throughput, which is essential in fulfilling the rising need for rapid production cycles

Smart manufacturing technologies facilitate real-time tracking and information evaluation, permitting companies to enhance machine efficiency and forecast upkeep demands. This proactive method not just decreases downtime however additionally extends the lifespan of devices. Moreover, using collective robotics, or cobots, enhances the flexibility of manufacturing lines, making it possible for makers and employees to run side by side safely and effectively.

The fostering of automation in plastic shot molding is not just a fad yet a tactical essential for companies aiming to continue to be affordable in an international market. By harnessing these modern technologies, makers can attain greater accuracy, lower waste, and adjust promptly to altering client needs, placing themselves for lasting development in a progressively automatic future.

Sustainable Materials and Practices

The push in the direction of automation and clever production has actually paved the way for a greater focus on lasting products and methods within the plastic injection molding sector. Firms are significantly seeking environmentally friendly alternatives to traditional petroleum-based plastics, leading to the fostering of recycled and bio-based materials. These lasting products not only reduce ecological effect but additionally straighten with consumer need for greener items.

Furthermore, collaboration between producers, material providers, and environmental organizations is fostering innovation in the advancement of lasting materials that meet performance criteria without compromising top quality. As policies around plastic use come to be more stringent, the market is poised to adapt by embracing these sustainable approaches, making certain lasting stability and minimizing dependence on non-renewable resources. The integration of sustainability right into plastic shot molding is not simply a trend; it is becoming an essential part of business obligation and operational quality.

Developments in 3D Printing

Recent advancements in 3D printing modern technology are substantially transforming the landscape of plastic shot molding. As soon as challenging or difficult to attain with traditional techniques, the integration of additive production processes enables for the rapid prototyping of complicated geometries top article that were. This capability not only increases product growth cycles but additionally decreases product waste, aligning with the expanding need for sustainable production practices

Additionally, the emergence of hybrid production techniques, which integrate 3D printing and shot molding, offers makers the ability to produce complex designs while preserving the performance of automation. This method makes it possible for the manufacturing of customized parts customized to specific customer demands without giving up the rate and scalability that injection molding offers.

Furthermore, innovations in materials, such as high-performance polymers and composites particularly made for 3D printing, are enhancing the practical abilities of published parts. These products can withstand higher anxiety and show boosted thermal residential or commercial properties, making them appropriate for even more requiring applications.

As 3D printing proceeds to advance, its assimilation right into plastic shot molding procedures assures to boost productivity, reduce costs, and foster innovation in product design, positioning manufacturers to better meet the challenges of a competitive market.

Information Analytics and IoT Assimilation

Information analytics and the assimilation of the Net of Points (IoT) go are reinventing plastic injection molding by offering producers with unprecedented insights right into their procedures. By leveraging real-time information gathered from interconnected devices and sensors, manufacturers can monitor efficiency metrics, recognize ineffectiveness, and enhance production procedures. This data-driven strategy assists in predictive maintenance, lowering downtime and expanding devices lifespan.

Furthermore, IoT assimilation permits enhanced quality assurance. By continually tracking variables such as cycle, pressure, and temperature times, suppliers can quickly spot variances from developed parameters and make changes in genuine time. This not just improves product consistency yet additionally minimizes waste and scrap rates.

The blend of data analytics and IoT modern technologies also encourages producers to take on more dexterous production approaches. With access to thorough data analytics, companies can react to market demands with greater versatility, adjusting production timetables and configurations as required. This adaptability is vital in a swiftly altering production landscape.

Modification and Layout Adaptability

How can customization and design flexibility boost the competition of plastic shot molding? In a significantly varied market, the capability to use tailored services is critical. Personalization allows manufacturers to meet specific customer demands, fitting special dimensions, shapes, and capabilities that typical items may not satisfy. This flexibility not just promotes client loyalty yet likewise opens avenues for brand-new service opportunities across numerous markets, from automobile to durable goods.

Innovations in style modern technologies, such as computer-aided style (CAD) and quick prototyping, additional bolster this pattern. These devices allow developers to create intricate geometries and elaborate patterns, which can be flawlessly integrated right into the production process. Therefore, producers can react promptly to altering customer preferences and market demands.

In addition, the implementation of modular tooling systems improves layout flexibility, enabling for quicker adjustments between different item layouts without comprehensive downtime. This flexibility can lead to decreased preparations and reduced production costs, making business extra agile and competitive. Inevitably, embracing customization and style versatility in plastic shot molding not just boosts product offerings but likewise enhances market positioning in an ever-evolving landscape.

Verdict

The future of plastic shot molding is defined by considerable developments in automation, sustainable practices, and cutting-edge products. Personalization through modular tooling and quick prototyping will certainly allow producers to remain responsive and competitive to the vibrant demands of the market.

The future of plastic shot molding is characterized by significant improvements in automation, lasting techniques, and cutting-edge materials.